- BMA:

2 Lemforder arms + 750 bushings pressed: $200 US

- Bavauto: 2 arms with performance bushings: $300.

- BMW: 2 arms no bushings: over $400 (always makes me laugh...)

Thrust arm bushings should always be changed in pairs. You

will need a press or find a shop with a press if you are not

changing the whole arm.

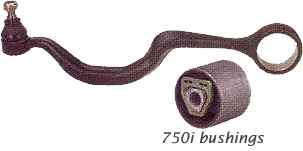

The BMW 750il and 850i have a stronger heavier bushing designed

for the greater weight of the BMW 750 and 850 front end and

engine. They give a firmer tighter suspension feel and steering

response. I would not change them until you have problems

with your existing bushing.If you have a fair number of miles

on your car when you do change them you may as well do the

arm and the bushing, since half the time the ball joint is

worn also.

Note from Dan Pitts

Thanks for the information concerning how to replace thrust

arms. One thing that may be helpful in the procedure is jack

up the wheel to take some load off of the ball joint before

trying to separate the ball joint from the wheel assembly.

I had two pickle forks completely wedged under the ball joint

with no movement. I reluctantly put the wheels back on (but

not the 22mm nut) and backed out of the garage to prepare

for a disgraced drive to the mechanic, when the ball joint

popped out. I then replaced the left thrust arm and resumed

work on the right side after this moment of joy, but this

time I placed the jack under the control arm ball joint and

took the load off of the thrust arm ball joint. This time,

the ball joint came right off using the pickle fork (actually

I used two due to the thickness of the boot). Anyway, thanks

for the procedure and the tip on replacement parts.

Note from Dan Trevor D:

On Friday I replaced the Sway bar link, Thrust arm and Control

arm on my ’89 535iA using the sections from your troubleshooting

section on the thrust and control arms as a guide.

One thing that I discovered was that to remove either the

Thrust arm and/or Control arm from the suspension mounting

plate, the following simplifies the procedure:

Once three bolts from suspension mounting plate are removed

Remove bolts from Control arm and Thrust arm Bushes.

Remove nuts from ball joints of Control arm and Thrust arm.

Remove sway bar link (17mm) from mounting plate.

Remove tie-rod from mounting plate with a tie-rod puller (I

bought one from Repco for $30, probably cheaper in the US)

Mounting plate with Control arm and Thrust arm can now be

easily removed

On your workbench you can now gently knock/tap out the ball

joint/s from the mounting plate with a pound hammer.

Reassemble.

I had initially struggled to try and remove the ball joint

ends of the Control arm and Thrust arm from the mounting plate

while still attached to the underside of the car.

Using the above procedure I estimate the total time to replace

Control arm, Thrust arm and sway bar links to be 1-1.5 hours

each side.

P.S. I used a trolley jack and 4 x axel stands – 1 under

each front jacking point and two under the cross member under

the engine.

Note from Rustam:

My tip is the following: The person should use a blade to

remove original ball joint boot such that no rubber of it

comes in contact with the fork that is used. The reason for

this is the following. If the rubber remains at any rate,

the pickle fork being driven with hard blows of the hammer

gets tu push right against the rubber which dissipates the

shock thereby cushioning the fork, precluding from break up.

If the rubber does not exist, the fork is driven directly

gainst the metal and the shock transfers wholly, imparting

maximum energy to metal. It takes no more than 5-10 energetic

blows for separation.

Consequently it is better to remove whole assembly along with

both arms and steering arm to preclude the shock transferring

to bushings as is already suggested by someone else.

|